A

few months ago I became interested in trying to make an automatic antenna

tuner. I had never thought about how they worked or what was used to

accomplish a product that would allow my radio to see a 1 to 1 match so I set

off to figure it out then apply what I had learned to make my own. I

almost always find a way to do something with my own twist so to speak so I

looked at autotuner designs that were already out there in the world. I

discovered that all of the tuners I looked at used a matrix or gang of

inductance coils along with input and output capacitance to reduce the SWR the

radio sees. In hindsight I understand why folks did their designs that

way. I had decided to purchase the parts for my design but later ended up

buying a cheap 3000 watt MFJ989C manual tuner and it came with everything I

needed to start my project.

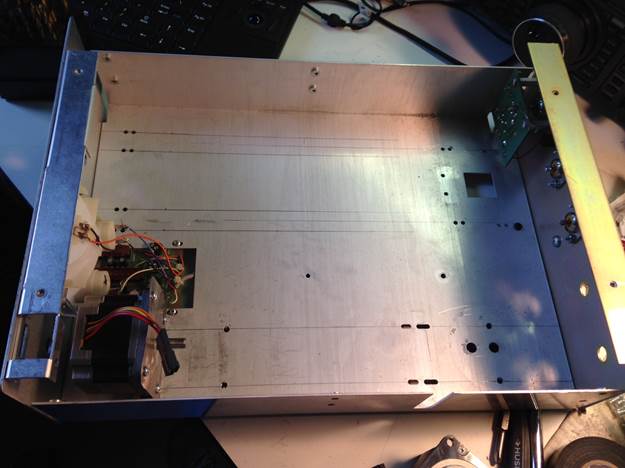

My

1st step was to strip the MFJ of all its components

to see what space I have to work with to install stepper motors to turn the

caps and inductor. I quickly learned that there was not enough room for

the steppers to be placed inside the cabinet to turn the caps but there was

enough room for the inductor if I moved it further back. I decided to use

servos to turn the variable capacitors since they only had to turn 180

degrees. At this point I did have to buy parts to make the connection of

the servo motors and the stepper to the shafts of each part.

I

took out the meter and made another front panel. I kept the SWR/Power bridge

from the MFJ.

While

I waited for the slow boat from China to arrive I started thinking about how I

manually tune my Palstar tuner to get the lowest SWR. So with trial and

error I did a basic design of the code. I need to say at this point how I

use my tuner is I listen for the noise level to increase as I adjust my

inductor. My 1st code did just this. It listened to the

noise level of the radio but a machine can’t tell the difference between quick

pop or someone on an adjacent frequency so it had no

accuracy using this method. I shifted gears and did it the old fashioned

way of finding the lowest SWR by turning the inductor and reading the SWR with

the processor. The capacitors were straight forward.

By

now my parts had come in and I started putting the parts back into the

MFJ. I left out the balun and the resistor used

for a dummy load. I also removed the coax switch so this tuner has no

bypass capability or use of the 2nd coaxial

input. I considered these as options because I needed to make sure the

tuner would work with my code before I invested money in vacuum relays.

Above

is the finished tuner.

Let

me explain at this point I had been working on the code the whole time not sure

what the outcome would be when I loaded into the tuner. After a week of

building and finishing the code I put it to the test and it actually

worked! Not every time mind you but it performed

as I would expect 80% of the time. Not good enough but I have a good

starting point.

The

code is simple. I try to do simple so folks can understand what they read

when they look at my software. The inductor is moved in blocks meaning it

makes 4 turns then reads SWR I later changed this to 1 turn to get better

accuracy (and it wasn’t good enough either) at the cost of tuning speed.

The unit does make a lot of noise. When it started up the 1st time my wife who

is a Dr. Who fan said it “Sounded like the Tardis” and it does! It makes

the sound because I decided to use the most robust library for the stepper

motor the AccelStepper Library and it uses acceleration and deceleration so it

starts slow winds up to speed the slows down to stop at exactly 1 turn.

The trouble is when the motor turns the analog read function I use to measure

the SWR doesn’t read till it stops. I added a rotary encoder later to

make fine adjustments. The servos that turn the caps worked perfectly so

I didn’t make any changes to that section. At this point (without the

encoder) the tuner was accurate now 99% of the time but a problem arose from

day one. How do I calibrate the unit so it keeps track of where it is so

it will not bang the end of the roller inductor.

When

the tuner is 1st turned on it thinks it is at 0 position which is all the way to the front of the

chassis. 8800 is all the way to the back. That is 44

revolutions. If it is sitting at, say 20 then it will try to make 24

turns while banging on the end of the inductor. This is a bad thing so I

made some endstop switches and mounted them on each end of the inductor.

Now when it reaches the back it sets the position to 8800 and I tell it to go

to 0 (The front) it stops then moves back to the correct location where it left

off and continues on. Did I mention this thing makes noise? While that

plan worked it would calibrate itself every time it was turned on and that

wasn’t acceptable to me. I ended up writing a routine so when the

inductor has found its best SWR it will write its location to the EEPROM in the

Arduino processor. This worked perfectly. Now when it is turned off

and back on again it knows exactly where it is so it backs up to 0 and starts

the process of finding the lowest SWR again.

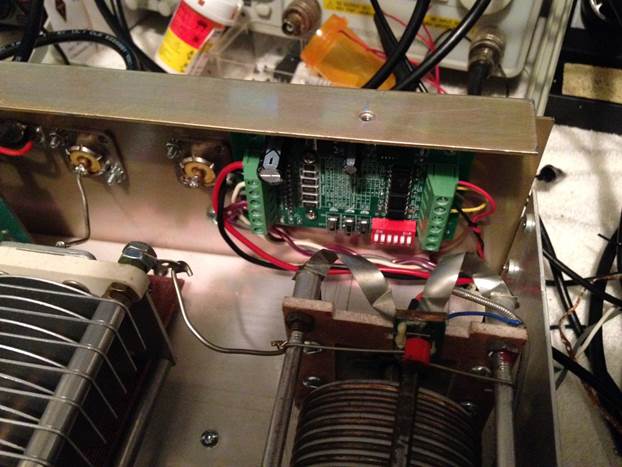

This

is the backstop I made and the stepper motor controller.

So

I still have it working 99% of the time. The answer was to add the rotary

encoder to make adjustments to the final resting stop. It does throw off

the EEPROM setting stored and can make use of the backstops to recalibrate but

it isn’t often enough for me to fret over.

Now

I want to display the power output and the SWR but I am out of pins to use

except for the serial TX and RX. I used a 2nd Arduino with a TFT

display/ touchscreen shield and connected it to the serial TX of the main

Arduino. On the display I connected it to the serial RX. Now all my

debug information shows up on the TFT screen. It didn’t work very well

and it had me frustrated to the point I put it to the side for weeks at a time

while I tried to make it display the data on each print from the main

Arduino. Through trial and a lot of error I got it working as well.

It shows the position of the 2 caps as well as the inductor. It also

displays SWR and Power output on each line like I wanted it to.

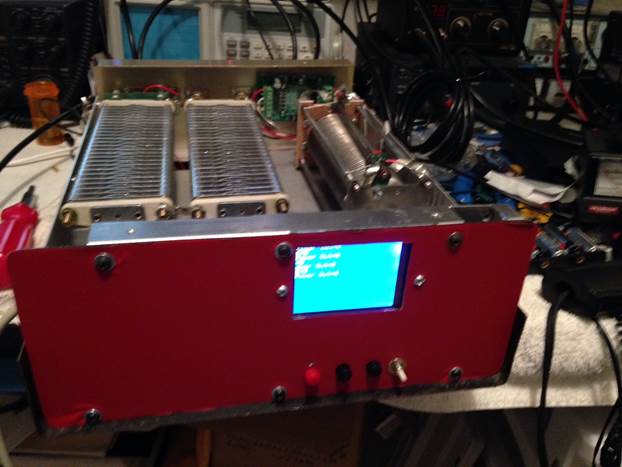

Above

is a picture before the encoder was installed and display was working properly.

I

have added the vacuum relays for antenna switching and bypass mode. I also updated the display to show all the parameters

while the tuner searches for the best match.

It is also better organized on the screen as well. The automatic band switching was interfaced

with the FT2000 and it sure does cut down on how long it takes to find a match. I was going to use a chip to translate the

band data from the radio but ended up using analog ports to accomplish this and

it works very well. I added a switch to

go from antenna 1 to 2. I don’t have

enough pins on the display shield to do touchscreen switching. At this point I have only 1 analog pin left

on the Arduino and all the other pins have been used. Bypass and tune modes are

selected by the rotary encoder momentary switch. If you can see the little

white button on the front, that is a reset switch for the Arduino that

calculates the match. I use it more as a

tune button that would need to be pressed every time you change bands.

The

code had been constantly changing so I haven’t posted it yet but will do so

maybe this weekend if I can finalize everything and run it through scenarios to

debug it. The code will be in 2

parts. 1 part is for the display and 1

for the tuner itself to calculate the best match. I will also start putting a parts list

together and try to get the information I have on paper (schematics) to and

electronic format. If you saw my

handwriting you would understand. I also

plan to go through the construction of the unit as well but it is pretty

straight forward. I don’t expect anyone

to make this exactly as I have.

This

is where I am at today. 2/11/16

Things

to do:

Test

the current code. It has been tested and is located here - Autotuner code It does have bugs on manual tuning.

Make

schematic.

Make

a Parts list.

Make

a “How To” page.

Add

a reset for the display. (No code changes)

Add

LCD for real-time Analog updates to power and SWR. (No code changes) (Add another Arduino and

create code for it to drive the LCD.)

**Work

on adding a mechanism to tell the tuner to “tune” when the band is changed. (When

not connected to a FT2K)

**Build

a small signal generator that can be tuned to the current band selected. (When not connected to a FT2K)

**Build

a frequency counter that can tell the Arduino what band to tune to when the

radio transmits momentarily. (When not

connected to a FT2K)

Look

into sharing pins so I can accomplish the statements above.

Add

photos of the current state of the tuner.

Consider using analog switches to free up pins on the Main Arduino.

**Options to add if desired (code changes)